Product details

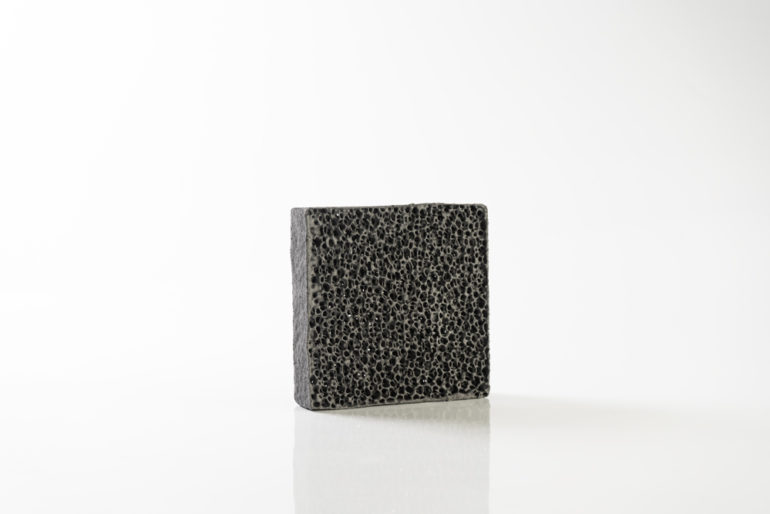

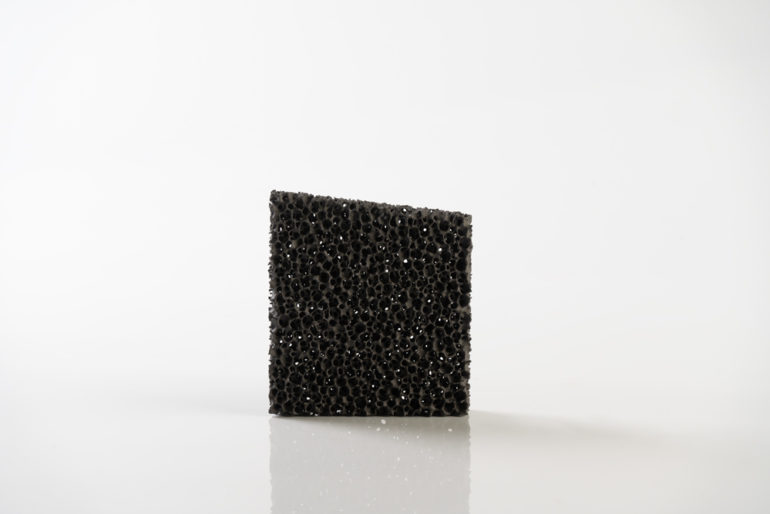

The Al2O3 – C based filters are intended for single filtering of aluminium and aluminium alloys up to the temperature of 850 °C.

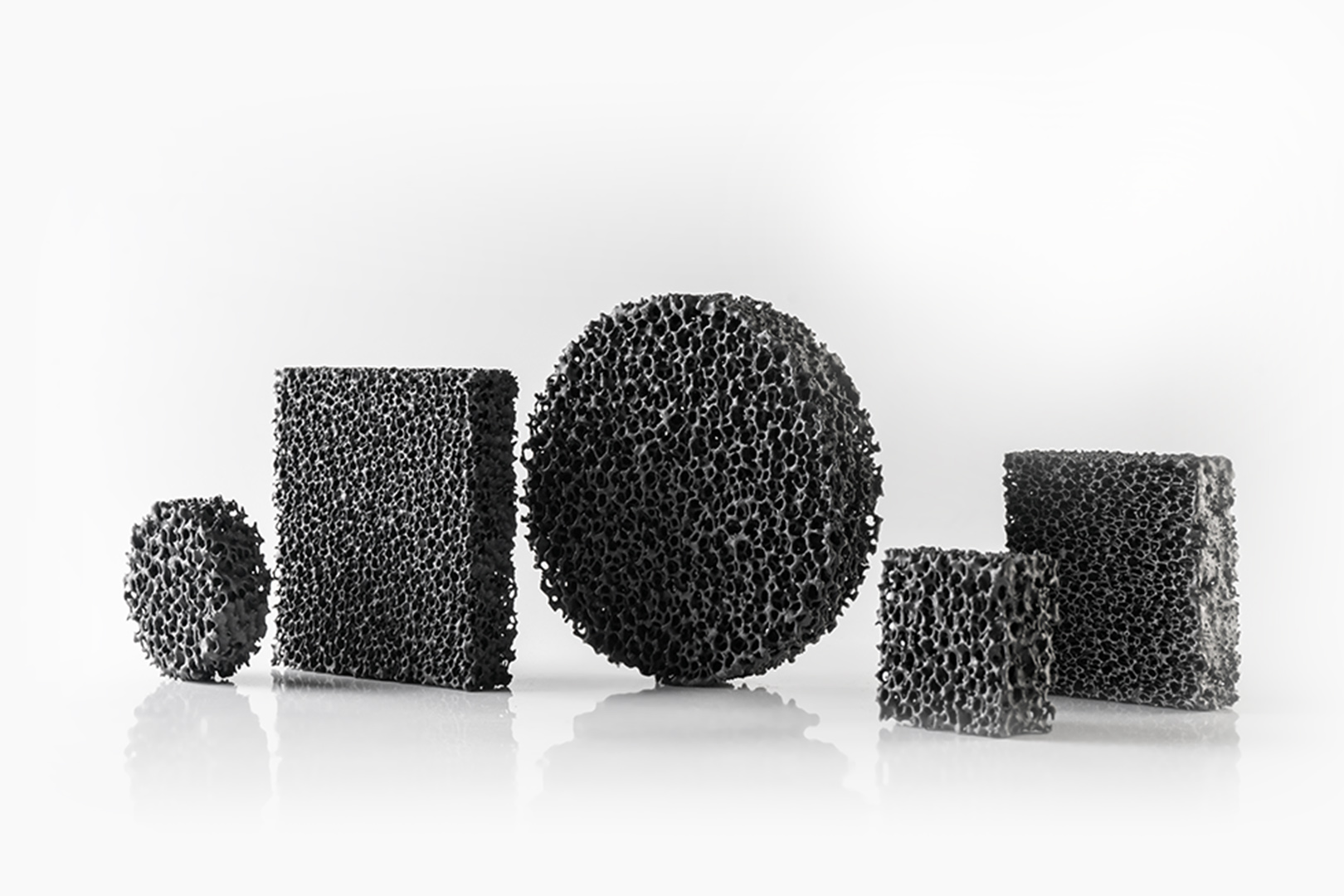

VUKOPOR® LD ceramic foam filters are designed for filtration of aluminium and aluminium alloys up to the temperature of 850 °C especially for gravity casting into sand, ceramic or metal dies. Low bulk density of the filter ceramics also allows trouble – free recycling of the returnable metal material with filter. During re – melting, the complete filter ceramics floats to the metal surface and can be removed easily, together with other impurities.

You can use VUKOPOR® LD ceramic foam filters in different positions inside of the gating system, or you can apply them in the combination with insulating or exothermic sleeves. Filters can be equipped with a sealing gasket to prevent them from crumbling within die assembling.

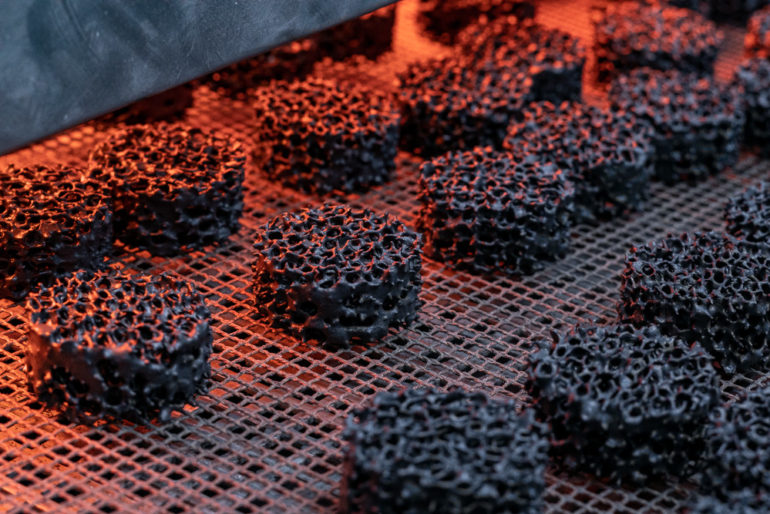

VUKOPOR® LD filters can´t be used for permanent submersion in the melt e.g. in holding furnaces or filter bowls. They are not recommended to be used in investment casting foundries from the reason of burning ceramic shells with filters in oxidizing atmosphere before casting.