Product details

The SiC based filters are intended for filtering grey and nodular iron and nonferrous metals at the temperatures up to 1480 °C.

VUKOPOR® S ceramic foam filters are designed for filtering castings of cast iron, bronze, brass and copper-alloys. The maximum recommended temperature of the application is 1480°C.

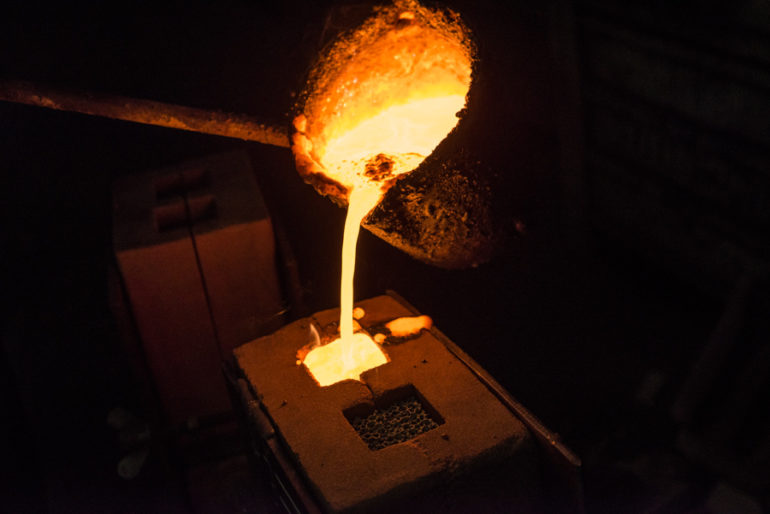

VUKOPOR® S can be used in filter prints of the gating system as well as for direct pouring on the filter in combination with exothermic sleeves. Moreover, they can be used in filter bowls for filtering of copper – alloys in casting campaigns. Filters can be used in filtration carousels and grates as well.

VUKOPOR S® ceramic foam filters make it possible to reduce the turbulence of the flow during mould filling and so prevent from creation of new inclusions and undesired defects of castings. This is possible because of turbulent flow of molten metal is transformed into laminar flow behind the filter.

The filters owe their qualities to the opened 3D structure of their ceramic matrix formed of a system of interconnected cells. They have very good heat conductivity, stability and resistance to sudden temperature changes. Chemical properties of the ceramic body allow very fast “priming” without any negative effect on metal.